What is ARbor wood?

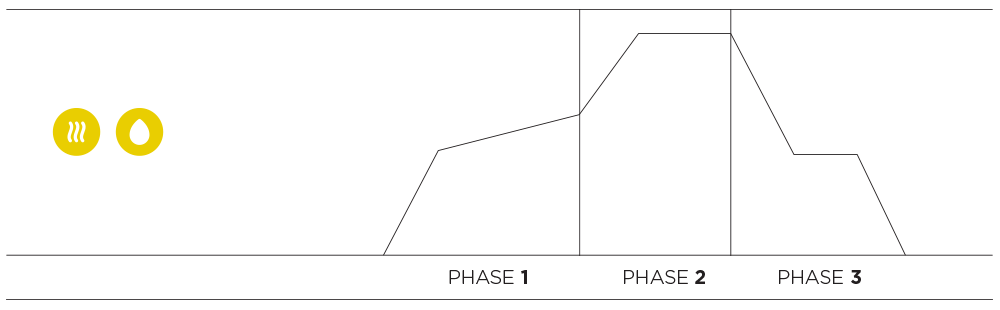

Arbor Wood is thermally modified wood produced in a specialized, 3-phase kiln chemical free process using only heat and steam. An initial gradual increase in temperature reduces the equilibrium moisture content (EMC) of the wood. Phase 2 sees a rapid spike in temperature and is where the magic really happens. The cellular composition of the wood is altered in this high-heat, oxygen-deprived environment which converts the natural acids and sugars so as to no longer be a food source for mold, rot or fungal decay. This change also renders the wood ‘hydrophobic’, meaning it loses much of the natural tendency to absorb water going forward. As a natural byproduct of the process the wood takes on a richer, dark tone throughout giving it a look similar to that of exotic species. The 3rd and final phase introduces steam to cool the wood down and bring the EMC back up to a suitable level.

Thermal modification is one of the most natural, chemical-free ways to extend the life of wood products.

Phase 1

Phase 2

Phase 3

Temperature Increase

The temperature in the modification kiln begins to increase, removing much of the pitch and sap in the wood. Steam is introduced to prevent the wood from checking in the high heat. The moisture content of the wood is reduced from 15-20% down to nearly zero.

Thermal Modification

Oxygen is removed from the modification kiln and peak temperatures are acheived. This high-heat, oxygen-deprived environment causes hydrolysis - a breaking of the bond between H2O and the wood’s hemicellulose. This phase is where thermal modification occurs.

Cooling & Re-Conditioning

Temperature is reduced by introducing steam. The steam cools and conditions the wood to a moisture content of 4-6% improving dimensional stability.

COLOR CHANGE

Thermal modification changes the naturally occurring sugars in the wood resulting in beautiful, rich tones that extend through the full thickness of the material. Since Arbor Wood is still a natural product, the grain and unique characteristics of the wood remain. In an exterior environment, Arbor Wood will move to gray when unfinished and the application of UV inhibitors help slow this process similar to non-modified products.

Properties

Dimensional stability is increased, minimal expansion and contraction

Enhanced appearance: darker, through-color and more even tone throughout

Increased exterior performance: less water absorption and less susceptible to rot

Able to be glued, painted, finished

Milling and workability similar to standard wood

Lightweight

Process is chemical free, only heat and steam are used

Is a value-added, new application for domestic wood

SUSTAINABILITY

Arbor Wood Co. is an FSC certified, US-based producer and is a premier choice for sustainably harvested thermally modified wood.

DOMESTIC

Arbor Wood Co. is based in Duluth, Minnesota and our timber is harvested domestically from FSC-managed forests.

CHEMICAL FREE

Thermally modified wood is an alternative to exotic woods and standard-treated woods. It attains superior exterior qualities without the use of toxic chemicals.

STABILITY

After the wood has been thermally modified its properties are more stable than standard kiln dried wood. The swelling and shrinking of wood due to moisture variations can be reduced by up to 60%.

DECAY RESISTANT

The risk of fungal attack is greatly reduced because thermally modified wood no longer contains sufficient nutrients.

INCREASED DIMENSIONAL STABILITY

Thermally modified wood is less susceptible to cupping and warping with changes in relative humidity.

ENHANCED APPEARANCE

Thermally modified wood will have darker through-color tones. Color will vary with cook temperatures and species. Like standard wood, thermally modified wood, if left untreated, will turn a weathered gray color over time.

WHERE TO USE THERMALLY MODIFIED WOOD

Thermally modified wood can be used in an array of commercial and residential applications. Popular applications are in external environments where moisture and humidity would compromise a lesser-grade material.

DECKING

DOCKS

SIDING

INTERIOR FLOORING

WINDOWS

DOORS

BATHROOM INTERIORS

SAUNAS

OUTDOOR FURNITURE

Improved aesthetics and durability are achieved with Arbor Wood Co. thermally modified wood. Our material can be used in place of more expensive tropical wood species and is an environmentally conscious option, proudly made in the USA.